| |

|

|

| |

HRH-YW型

系列淋雨环境试验室(人工气候试验室)仿真模拟设备系统装置 |

|

| |

HRH-YW

series rain environmental test chamber (artificial climate

laboratory) equipment system simulation device |

|

| |

|

|

| |

|

|

| |

1、设备规格:

(1) 规格:喷头点阵由1个框架2000*6000mm组成。共260个喷嘴。

喷淋有效面积 约2000×6000mm;可以按用户实际要求选择定制。

(2) 降雨量的可调节工作范围0.2~250mm。

(3) 水泵电机:功率5.5kW,电压380V,3相交流。

降范围 能模拟降雨量从水量0.2~250mm之间实现任意无级调节。

淋雨时间 可任意设定试验周期,试验时间。

环境模拟装置喷淋有效面积约2000×6000mm,喷嘴做工精细,具有耐酸碱盐防腐蚀功能。

环境模拟装置进水装置前配置净化设备,能实现净化功能的设备,避免喷淋装置堵塞。 |

|

| |

|

|

| |

2、设备适用范围:

(1)喷雨设备适用于铁路高速动车组车顶的水式和湿式试验。火车,飞机,汽车,电力设备产品及户外运行设备;质检鉴定计量检测监督机构,电力设备制造厂,铁路及其通信,航空航天和航空航天飞行器,军工科研单位,大专院校以及建筑物与气象等部门的带电环境模拟考核试验。

(2)喷雨设备能保证在长6m,宽2m范围内持续均匀降下滴状雨,雨滴细小均匀。 |

|

| |

|

|

| |

3、设备实现的淋雨条件:

设备工作时在有效区域内必须满足下表(GB/T 16927.1-2007-高压试验一般要求)的全部淋雨要求。能够人工模拟降雨、盐雾、下雪、冰冻等环境条件和自然灾害,研究不同环境条件下对高电压运行设备的影响,重点侧重淋雨和盐雾试验环境的模拟。 |

|

| |

|

|

| |

人工气候试验室主要技术参数要求如下: |

|

| |

技术参数 |

参 数 指 标 |

★盐水盐度 |

2.5,3 .5,5 ,7 ,1 0,14, 20, 28, 40, 56, 80, 112,

180kg/m3 and 224kg/m3 |

喷雾方式 |

气流喷雾式,连续/间隙任意 |

★降水量范围 |

能模拟降雨量从0.2~250mm(小雨、中雨、大雨、暴雨、特大暴雨)之间实现任意无级调节 |

淋雨时间 |

可任意设定试验周期,试验时间 |

|

|

| |

|

|

| |

分 类 |

单位 |

数值 |

所有测量点的平均淋雨率 |

垂直分量 |

mm/min |

1.0~2.0 |

水平分量 |

mm/min |

1.0~2.0 |

单独每次测量和每个分量的极限值 |

mm/min |

平均值±0.5 |

收集到的雨水温度 |

℃ |

周围环境温度±15 |

|

|

| |

|

|

| |

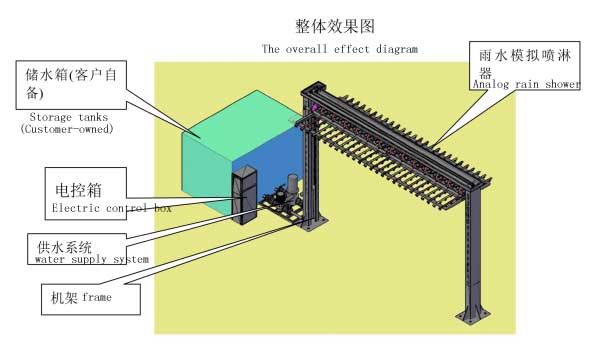

4、淋雨设备原理简图: |

|

| |

|

|

| |

说明:喷雨设备必须满足距产品安装最短距离H不小于1.5米,并且能降下满足招标技术文件要求的降雨。 |

|

| |

|

|

| |

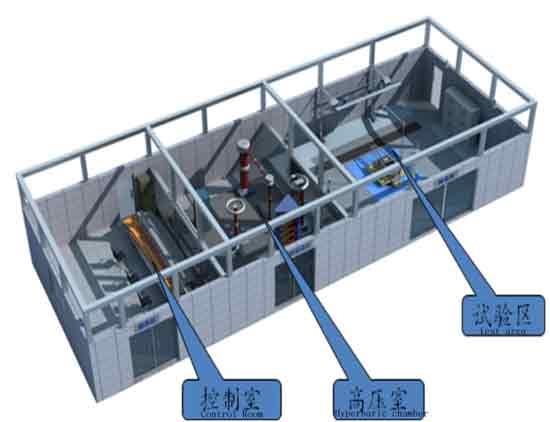

5、设备结构及功能:

(1) 雨水模拟喷淋器采用SUS316#不锈钢材质制作,做工精细,具有耐酸碱盐防腐蚀功能,喷头内套镶红宝石,其连续使用寿命可长达5-10年。

(2) 喷嘴结构采用独特的设计,使其喷射不连续线状(雨点状)水平距离六米以内无水雾,喷射方向±30度水平角电控可调,变频控制与电磁阀控制结合,模拟降雨量从0.2~250mm(雨雾、小雨、中雨、大雨、暴雨、特大暴雨)之间实现任意无级调节。根据需求,以后本装置还可以改造升级,还能进行污秽、尘埃、霜冻及冰雪等自然灾害状况的模拟。

(3) 设备结构

本淋水系统装置由如下3部份组合而成。 |

|

| |

|

|

| |

1、喷头点阵

1):喷头采用SUS316#不锈钢材质制成,耐酸碱盐防腐蚀性强。

2):喷头与输水管采用丝牙连接方式,便于拆卸、更换、方便清洗及保养。输水管采用高纤维塑胶高压(高电压:35kV以上)软管,耐磨抗压

3):喷头仰、俯角度由低速电机传动控制,角度精确。

4):喷头点阵框架可电动控制在两个方向轴上±90度转动,实现水平喷雨与竖直喷雨的需求。

5):每排(10个喷头)各由一个电动开关阀门控制,共26个电动开关阀门。

6):喷雨器与底架之间采用高压绝缘的方式连接。 |

|

| |

|

|

| |

2、电气控制部分

采用优质接触器、电磁阀等电器元件和高性能的变频器及电动机,精确的逻辑电气控制设计;美观实用的计算机全自动测控操作台,操纵自如,安全可靠,操作台统一放置在控制室。 |

|

| |

|

|

| |

3、供水部分

1): 蓄水箱采用SUS316#耐酸碱盐不锈钢材料,箱体不锈钢材料的厚度为2mm。配以水位观察计,能有效的保证喷淋数据的采集。下底有排水口方便箱体清洗。根据需要配套相应大小的蓄水箱。

2): 采用流量8m3/h、扬程25米的小型水泵加压加温喷淋,并以变频调节控制,能保证模拟喷雨量在0.2~250mm精确控制。

3): 供水部分需安装便于维护的过滤装置(过滤网等)及净化装置,确保水路不被杂物或者水垢堵塞。 |

|

| |

|

|

| |

6.实物图片: |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

HRH-YW

series rain environmental test chamber (artificial climate

laboratory) equipment system simulation device |

|

| |

|

|

| |

1, equipment specifications:

(1)Specifications: Sprinklers lattice consists of a frame

composed of 2000 * 6000mm. A total of 260 nozzles. Spraying

an effective area of about 2000 × 6000mm; can be customized

by the user to select the actual requirements.

(2) precipitation adjustable operating range 0.2 ~ 250mm.

(3) pump motor: Power 5.5kW, voltage 380V, 3-phase AC. Down

range can simulate rainfall stepless adjustment from 0.2

to achieve any water between 250mm. Rain test cycle time

can be arbitrarily set, test time. Environment simulator

spray effective area of about 2000 × 6000mm, the nozzles

fine workmanship, with acid and alkali salt corrosion function.

Environmental simulation device before the water purification

equipment device is configured, can achieve purification

equipment, to avoid clogging the spray apparatus. |

|

| |

|

|

| |

2, the device Scope:

(1)Rain spray equipment suitable for high-speed rail EMU

roof water and wet test. Trains, planes, automobiles, electrical

equipment and outdoor products operation of the equipment;

quality control oversight bodies identified measuring and

testing, electrical equipment factories, railways and communications,

aerospace and aerospace vehicles, military research institutes,

universities and building and meteorological departments

charged environment simulation assessment test.

(2) spraying equipment to ensure the long rain 6m, continued

even lower over a wide range of 2m rain droplets, raindrops

small uniform. |

|

| |

|

|

| |

3, the device achieved rain conditions:

When the device is working within the effective area must

meet the following table (GB / T 16927.1-2007- general requirements

for high-voltage test) requirements of all the rain. Capable

of artificial rainfall, salt fog, snow, ice and other environmental

conditions and natural disasters, the impact study under

different environmental conditions for high-voltage operation

of equipment, focused mainly rain and salt spray test environment. |

|

| |

|

|

| |

Artificial

climate test chamber main technical parameters are as

follows: |

|

| |

| Technical Parameters |

Parameter index |

| ★ brine salinity |

2.5,3 .5,5 ,7 ,1 0,14, 20, 28, 40, 56, 80, 112,

180kg/m3 and 224kg/m3 |

| Spray method |

Airflow spray, continuous / gap any |

| ★ precipitation range |

can simulate rainfall 250mm (light rain, moderate

rain, heavy rain, heavy rain, torrential rain) from

0.2 to achieve any stepless adjustment |

| Rain time |

It can be arbitrarily set the test cycle, the test

time |

|

|

| |

|

|

| |

| Classification |

Unit |

Numerical |

| The average rain rate for

all measurement points |

Vertical component |

mm/min |

1.0~2.0 |

| Horizontal component |

mm/min |

1.0~2.0 |

| Individually for each measurement and

limit values for each component |

mm/min |

Average data±0.5 |

| Collected rainwater temperature |

℃ |

Temperature ±15 |

|

|

| |

|

|

| |

4,Shower simplified schematic

of the device |

|

| |

|

|

| |

|

|

| |

|

|

| |

Description: Spray equipment must meet

the minimum distance H from the product installation is

not less than 1.5 meters, and can be lowered to meet the

requirements of the tender technical documents rainfall. |

|

| |

|

|

| |

5, the device structure and function:

(1) Analog rain shower uses SUS316 # stainless steel production,

fine workmanship, with acid and alkali salt corrosion function,

inlaid ruby set within the nozzle, its continuous life of

up to 5--10 years. (2) the nozzle structure unique design,

so that the ejection discontinuous lines (like rain) horizontal

distance of no less than six meters mist spray direction

± 30 ° horizontal angle adjustable electric control, frequency

control and electromagnetic valve control combination, simulated

rainfall between 0.2 ~ 250mm (fog, rain, moderate rain,

heavy rain, heavy rain, torrential rain) from arbitrary

stepless adjustment. According to the needs of the future

of the device may also be upgrading, but also to simulate

the contamination, dust, frost and snow and other natural

disaster conditions. (3) Device Structure The water spray

system means a combination of the following three part together. |

|

| |

|

|

| |

1, the nozzle lattice

1): nozzle made of SUS316 # stainless steel, acid salt corrosion

resistance is strong. 2): Sprinklers and water pipes using

dental wire connection, easy to remove, replace, easy cleaning

and maintenance. High-fiber plastic pipes high pressure

(high voltage: 35kV above) hose, wear compression 3): Sprinklers

Yang, overlooking the angle formed by the low-speed motor

drive control, accurate angle. 4): Sprinklers lattice frame

of electrically controlled in both directions of rotation

axes ± 90 degrees to achieve the level of the vertical jet

spray rain rain needs. 5): each row (10 nozzles) each controlled

by an electric switch valve, a total of 26 electric switch

valves. 6): The spray wipers and the chassis between high

voltage insulation fashion. |

|

| |

|

|

| |

2, the electrical control part Using

high-quality contactors, solenoid valves and other electrical

components and high-performance inverter and the motor,

precise electrical control logic design; aesthetic and practical

computer fully automatic monitoring and control console,

operated freely, safe, reliable, unified console is placed

in the control room. |

|

| |

|

|

| |

3, part of the water supply 1): storage

box with acid salt SUS316 # stainless steel materials, stainless

steel cabinet thickness is 2mm. Together with the observed

water level meter, which can effectively ensure the data

collected spray. By the end of a drain tank easy to clean.

According to the need to complete the appropriate size of

the storage tanks. 2): The flow rate 8m3 / h, head of 25

m small pump spray pressure and heat, and to adjust the

frequency control, to ensure that simulate spray 0.2 ~ 250mm

rainfall precise control. 3): Water filtration apparatus

part to be installed to facilitate maintenance (filters,

etc.) and purification devices to ensure water is not blocked

by debris or scale. |

|

| |

|

|

| |

Physical picture |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|